DTG - Direct to Garment Printing

Direct to Garment ( DTG )

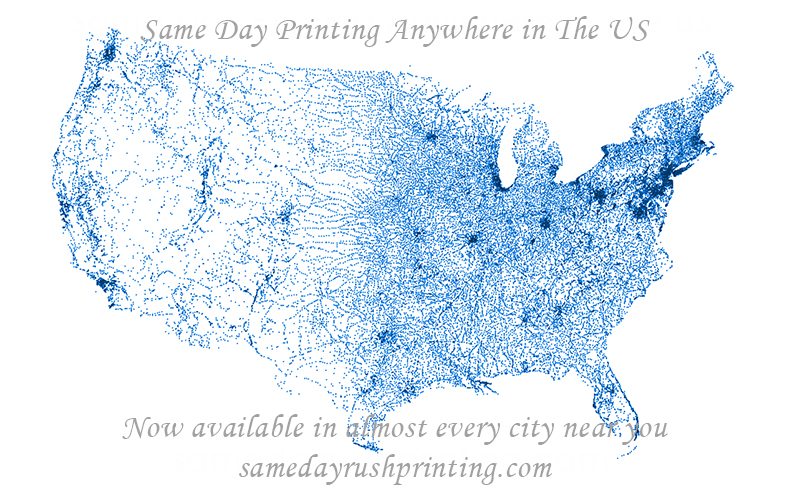

Same Day Printing & Same Day Delivery - Open 24/7

Conveniently Offering the fastest highest quality direct to garment printing for all your rush same day printing needs.

Order & Design Online

Our digital printing services are available for same day printing and to all our customers for a variety of occasions. Let your inventiveness run wild, as our computerized innovations let us print impacts you've never envisioned were conceivable. Possibly you oblige white ink on an agreeable static stick (or a mixed bag of other particular papers), or you must nail that correct corporate color that must be accomplished as a spot shade (not transform)… not an issue! On the off chance that its a personalized print arrangement that is needed, our variable information abilities are there to address your needs. Simply send us an exceed expectations spreadsheet alongside your craft documents and we'll do the rest!

Convincing correspondences are a crucial segment of attaining results. We've been fulfilling the most requesting clients on the planet in excess of 40 years. What's our mystery? We realize what you need and we convey it – at New York minute.

Here at Same Day Rush Printing, We can customize with specialty inks direct to garments such as t-shirts, sweatshirts, aprons, hats, tank tops, and more. With direct to garment printing, there are NO SET UP FEES or messy screens as with traditional silk screen printing. At Same Day Rush Printing, We use the latest direct to garment printers and top-of-the-line software to create vibrant detailed graphics. CONTACT US NOW! Together we will come up with great solutions to bring your ideas to life.

Whether you are launching your own brand or just customizing your personalized t-shirts, sweatshirts, aprons, hats, tank tops, and more, DIRECT TO GARMENT PRINTING is great. Direct to garment printing will give vibrant colors with a soft feel. Our direct to garment services are great for start-up brands as there are no minimums. Here at Same Day Rush Printing, We can print either one shirt or thousands and all of our made in-house. Not to mention, your customized DTG will be of the highest quality. Direct to garment printing is the perfect choice when your design requires many colors and precise details, such as photographs. Hands down DTG printing is the best method to use. It is very important to make sure that you have a look that is truly yours as well as something that represents you and your brand.

Order DTG (direct to garment) Online

To start your order for this printing service you can use the search bar to look up the specific product you want to purchase then within the printing method of each product you would select the default to DTG (direct to garment). To make it easier for you we have compiled a small list of products pertaining to this specific printing service but keep in mind that this printing service is offered in even more products than what you see below.

- Aprons

- Face Masks

- Bandanas

- Hats & Caps

- Infant Apparel

- Long Sleeve Shirts

- Polo Shirts

- T-Shirts

- Sweatshirts

- Tank Tops

- Tote Bags

View Location Details Below:

NYC - New York City • LA - Los Angeles • Chicago • Houston • Phoenix • Philadelphia • San Antonio • San Diego • San Fransico • Dallas • San Jose • Miami • Las Vegas • Boston • Washington D.C. • Seattle • Jacksonville

Same Day Direct To Garment Printing (DTG)

Direct to garment printing, also known as DTG printing, digital direct to garment printing, digital apparel printing, and inkjet to garment printing, is a process of printing on textiles and garments using specialized or modified inkjet technology. Same Day Rush Printing provides the same high-quality, fast, and reliable service you have come to love and expect in a wide-range of direct to garment applications. Same Day Rush Printing has built a one-of-a-kind reputation in New York for doing high quality work, combined with very fast turnaround and competitive pricing.